PRODUCTS

Based on accumulated experience and technological innovation, we strive to provide the highest quality and service.

PRODUCTS

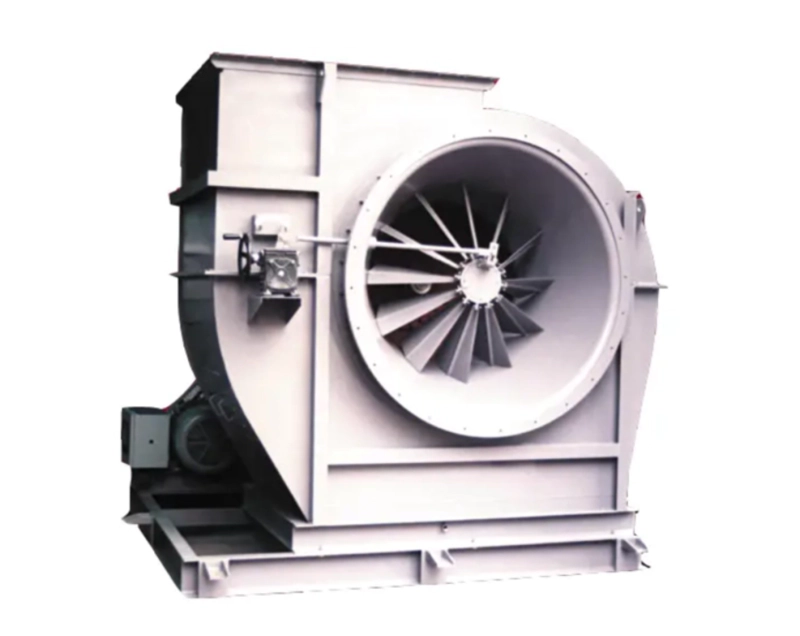

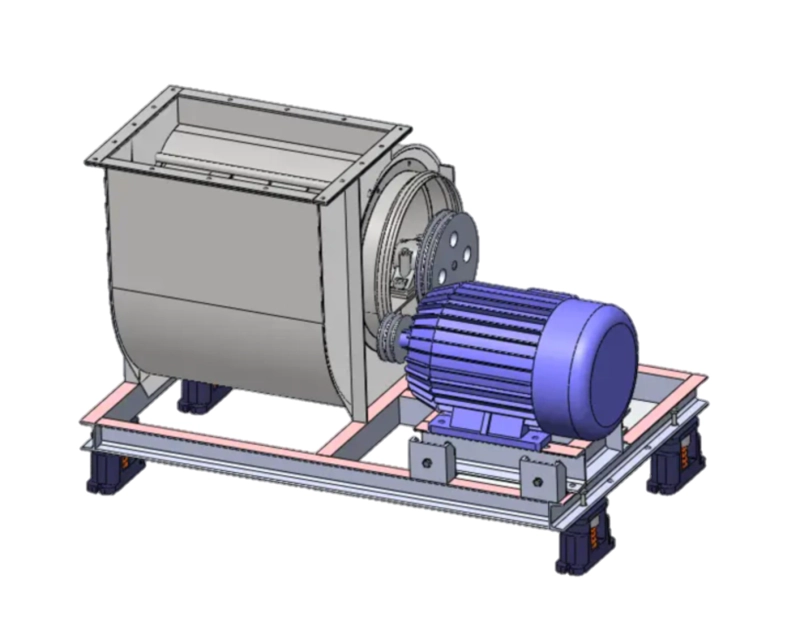

AIR FOIL FAN

Our AIR FOIL FAN is one of the most widely used products across various industries.

Based on years of manufacturing experience and technology, it has been supplied to numerous industrial sites, including Samsung Semiconductor plants.

Through continuous research and testing, we have developed high-efficiency and low-noise AIR FOIL FANs with improved performance, earning strong trust from our customers.

We will continue to strive to deliver the highest quality and service through accumulated experience and technological innovation.

Blade Shape

• Long blade length with narrow width

• Suitable for 50mmAq ~ 350mmAq (high airflow, medium static pressure)

• Double-surface airfoil design with backward-curved blade profile

• Fewer blades (10~12 blades)

Product Features

• Highest efficiency at the same airflow and static pressure point

• Low noise even at high speed due to smooth airflow through the airfoil section

• Slight change in static pressure depending on airflow variation, but no change in power consumption

• Suction vane damper installation enables smooth airflow control and efficient energy management

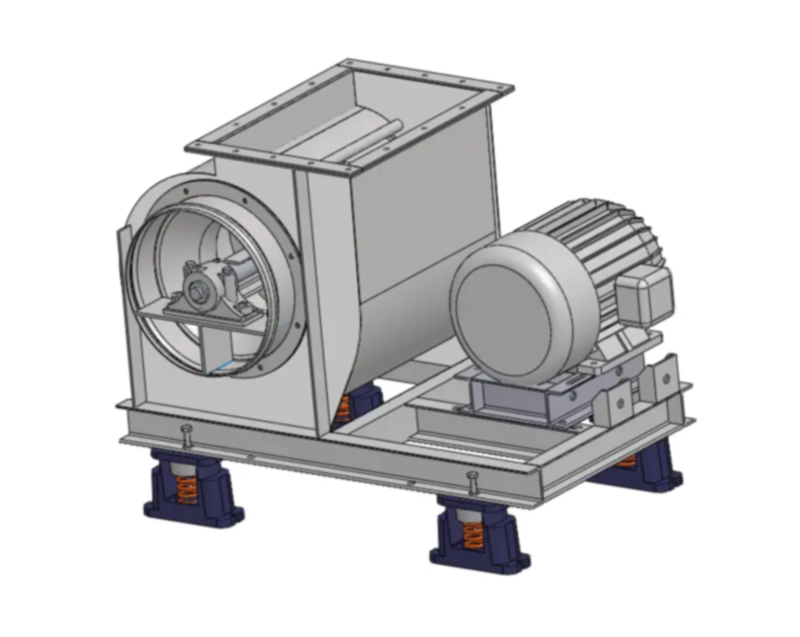

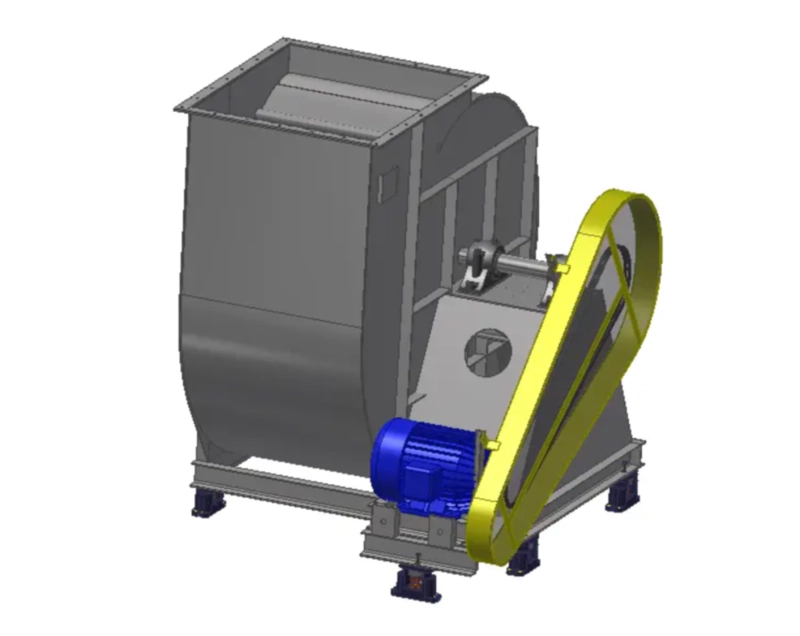

SIROCCO FAN

Sirocco fans have multiple blades, making them operate mainly at low speed and ensuring relatively quiet operation.

They are used for high airflow and low static pressure applications (static pressure 15 ~ 70mmAq).

Although the static pressure fluctuation is small with changes in airflow, power consumption increases rapidly when operating below the rated static pressure.

(Applications: Parking lot supply/exhaust, various HVAC and ventilation systems)

Blade Shape

• Short blade length and wide width

• Suitable for 15mmAq ~ 70mmAq (high airflow, low static pressure)

• Forward-curved blade with the tip bent toward the rotation direction

• More blades compared to other types

Product Features

• High airflow, low static pressure structure compared to other types, requiring less installation space

• Quiet operation with low noise due to low-speed operation depending on impeller shape

• Small change in static pressure with airflow variation

• Easy airflow and static pressure control with vane damper installation, enabling efficient energy management

• Power consumption increases rapidly when operating below the rated static pressure

IN LINE FAN

IN LINE FAN uses adjustable blades that allow airflow control, enabling economical operation.

The inlet is shaped like a cone, and a guide vane is installed at the rear, making it a low-noise structure.

It is designed in a rectangular duct shape, making installation easy. It is lightweight and compact, requiring the least installation space among fans with the same capacity.

Additionally, multi-layer stacking allows high-airflow operation.

(Applications: Parking lot supply/exhaust, fire protection & smoke control ventilation, mechanical rooms and electrical room ventilation systems)

Blade Shape

• Mixed blade structure combining centrifugal and axial flow, with a blade angle of 45°~55°. Suitable for 10mmAq~100mmAq (medium airflow, low static pressure)

• Wide blade width, fluid enters at approximately 45° and flows along the boss

• 9 blades with adjustable pitch and 5 performance levels. Bolt-fastened structure manufactured by mold, not welding — lightweight with low starting load

Product Features

• Low noise due to aerodynamic design of inlet cone and discharge guide vane

• Easy rectangular duct connection and smallest installation space among fans of the same capacity

• Small static pressure fluctuation and low power variation according to airflow changes

• Adjustable blades allow airflow control for economical operation

• Secondary noise reduction using sound-absorbing material (G/wool 50t × 40Kg/Cm²), lowest noise among same-capacity fans

• Lightweight and compact, easy duct installation

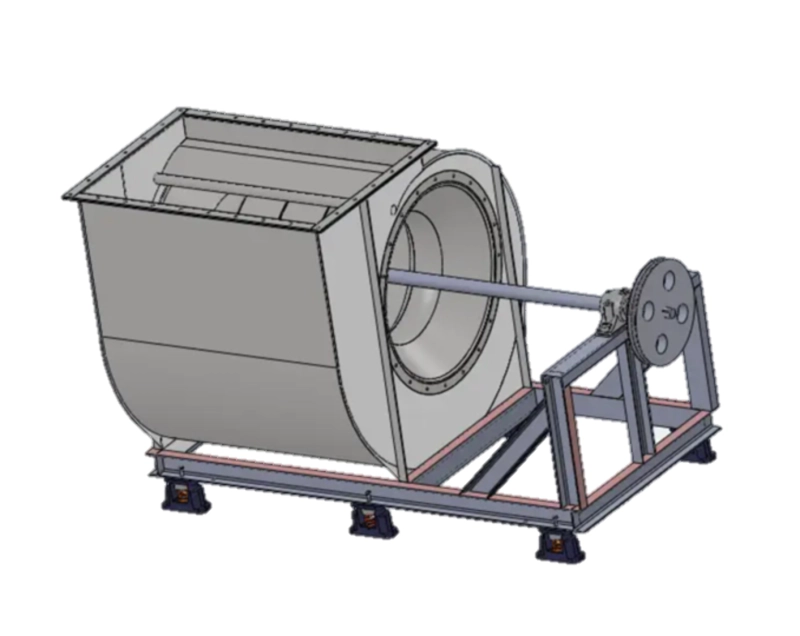

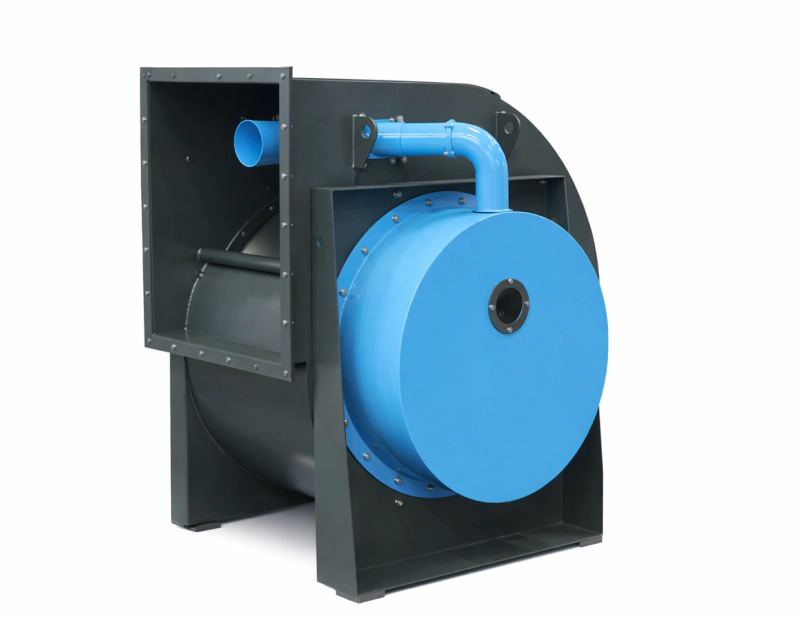

AXIAL FAN

AXIAL FANS use adjustable blades made of aluminum casting and E.P.Y materials,

allowing airflow control and enabling economical operation.

The blade insertion type into the central hub allows changing the number of blades,

but a drawback is relatively higher noise.

They are used for high-airflow, low static pressure applications (15~80mmAq),

and allow large-volume airflow control.

(Applications: Subway ventilation, tunnel ventilation, fire smoke exhaust systems, painting facilities)

Blade Shape

• Airfoil cross-section (15mmAq~80mmAq: high airflow, low static pressure)

• Axial inlet and axial discharge through guide vanes or spinner

• 4~18 adjustable blades for easy airflow control

• Materials: Aluminum casting, G.R.P, etc.

• Direct coupling in 2-stage or multi-stage configuration to increase static pressure

Product Features

• Used for high airflow, low static pressure points

• Small variations in static pressure and power consumption depending on airflow changes

• Compact installation and easy setup compared to other fan types

• Relatively high noise due to airflow friction in axial flow through ducts

• Wide-range volume control with adjustable blades allows large-scale airflow control and economical operation

• Silencer parts can be added to reduce noise caused by high airflow

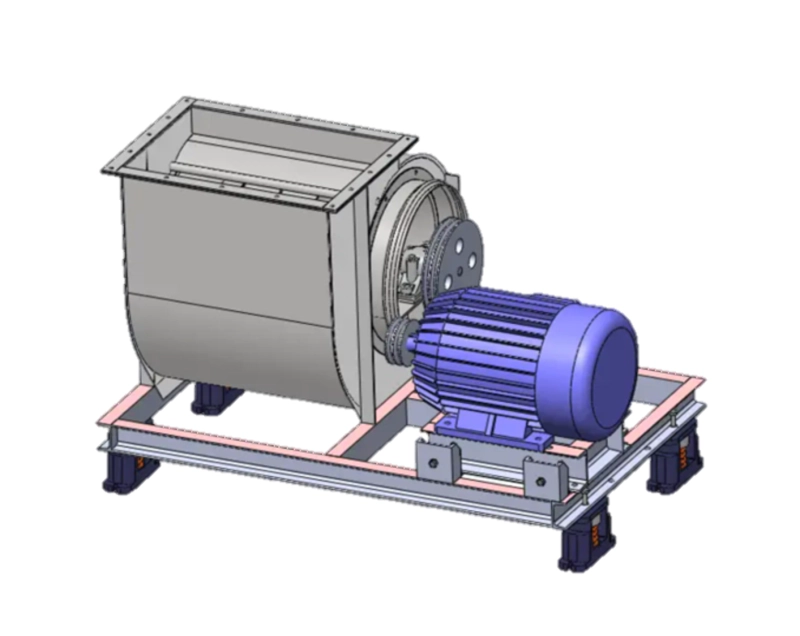

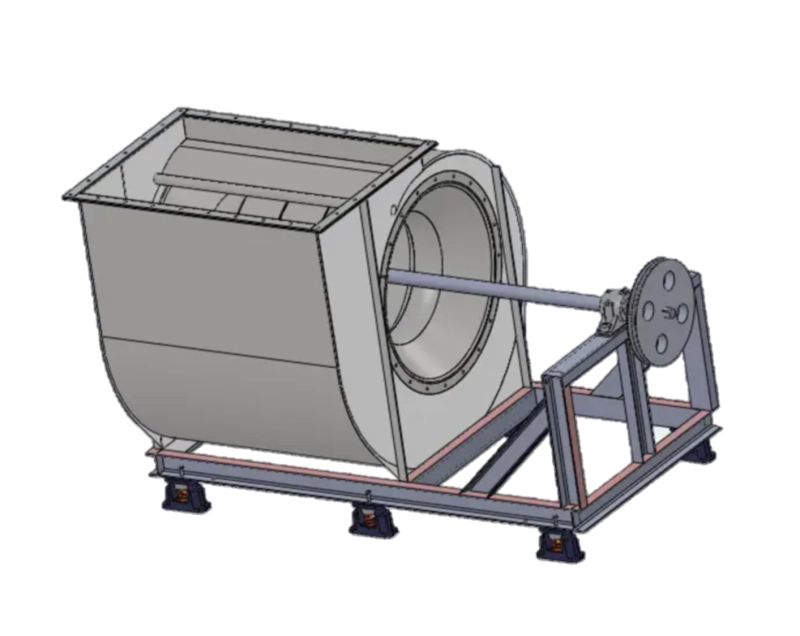

PLUG FAN

PLUG FAN applies airfoil and radial blade shapes and is used for medium airflow and medium static pressure applications (static pressure 50~250 mmAq).

It is installed embedded into a wall.

Its interior has a double-structure.

The bell-mouth edge is attached to the inner wall surface, and the blades are positioned between the inner and outer wall surfaces, allowing internal fluid to disperse and circulate within the wall.

(Applications: Underground parking lots, annealing furnaces, electric furnaces, etc.)

Blade Shape

• Long blade length and narrow width

• Curved backward in the rotation direction (airfoil cross-section)

• Fewer blades than other fan types

Product Features

• Highest efficiency at the same airflow and static pressure point

• Smooth airflow with airfoil blades ensures low noise even at high speed

• Slight static pressure variation with airflow change, but no change in power consumption

• Suction vane damper enables smooth airflow control and efficient energy management

NEW PRODUCTS

ADFB–EC(TWIN)

A high-efficiency, energy-saving product applied in building facility spaces as an HVAC and ventilation blower, featuring control operation through EC control.

Product Features

• Minimizes motor and drive components, reducing installation space and improving spatial efficiency

• Built-in motor overheat protection with self-air-cooling system (patent pending)

• EC motor with durable bearings, built-in stepless speed control, IE5 efficiency rating, Class F insulation, and IP55 protection rating

• Multi-voltage motor support – 220 / 380V, 254 / 440V, 265 / 460V, 277 / 480V

• Durable structure with anti-corrosion powder coating and operating temperature range of -20~65℃

• Optional: Smart sensing control (temperature, humidity, airflow speed, gas concentration, etc.) to maximize efficiency and reduce operating cost

• Material can be selected according to order: GI-sheet, STS-sheet, Mild Steel

Main Applications

• Semiconductor equipment, fume hood exhaust systems

• Clean room booth supply/exhaust systems

• HVAC equipment such as A.H.U and OAC

• Drying equipment, nuclear power plant and local ventilation systems

• Subway tunnel air supply/exhaust, air washer systems

• Other general industrial forced-air systems

ASFB–EC(SINGLE)

Applied in building facility spaces as an HVAC and ventilation blower. A high-efficiency, energy-saving product with control operation through EC control.

Product Features

• Fan structure minimizing motor/driving components → reduced installation space, improved spatial efficiency

• Built-in motor overheating protection with self-air-cooling system (patent pending)

• EC motor with durable bearings, stepless speed control, IE5 efficiency rating, F insulation class, IP55 protection rating

• Multi-voltage motor support: 220/380V, 254/440V, 265/460V, 277/480V

• Strong structure with anti-corrosion powder coating, operating temperature range −20~65℃

• Optional: smart sensing control (temperature, humidity, speed, gas concentration, etc.) to maximize efficiency and reduce operating cost

• Material can be selected per order: GI-Sheet, STS-Sheet, Mild-Steel

Main Applications

• Semiconductor equipment, fume hood exhaust

• Clean room booth supply/exhaust

• HVAC equipment such as A.H.U and OAC

• Drying equipment, nuclear power plant/local ventilation

• Subway oil-film supply/exhaust, air washer systems

• Other industrial forced-air systems

AXF–SE-F300&F400

• Dedicated product for fire smoke exhaust

• Smoke exhaust fan certified for 400℃/2hr and 300℃/2hr – F400 / F300

• Performance verified at 300℃/2hr in fire-hazard areas (KTC – Korea)

Fan

• Axial-type strong steel pipe casing with high structural rigidity

• Cast aluminum impeller (adjustable pitch for performance control)

• Impeller made of special alloy material ensuring heat resistance

Motor

• Designed for emergency (high-temperature fire conditions) with Class H insulation – heat-resistant performance certified

• Certified test completed for 300℃ / 2 hours operation by authorized agency (KTC)

MFA–EC/MFB–EC

An inline fan applied to local ventilation for building supply/exhaust systems, featuring low noise and high efficiency with EC control.

Product Features

• Strong galvanized sheet structure with built-in soundproof and heat insulation device (25mm or more)

• Structure designed to minimize airflow turbulence and maximize space efficiency (patent pending)

• Centrifugal, low-noise product equipped with compact EC motor and Smart Control System for controlling air quality, temperature, humidity, and airflow speed

• Bottom-open structure for easy inspection and maintenance

• Multi-voltage motor support – 220 / 380V, 254 / 440V, 265 / 460V, 277 / 480V

• Anti-corrosion powder coating and centrifugal flow structure enabling easy duct connection (patent pending)

• Two types of impellers depending on airflow and static pressure (high volume / low static pressure & medium volume / high static pressure)

• Improved efficiency with centrifugal scroll application

Main Applications

• Semiconductor equipment, fume hood exhaust, and local ventilation

• Clean room booth supply/exhaust (FCU, FFU)

• Explosion-proof structure with spark-prevention function

• Drying systems, nuclear power plant local ventilation

• Hospital facilities, special environmental airflow control (Smart Control)

• Applicable to horizontal and vertical installation (multi-directional air inlet support)

PLF Series(EC)

Duct-connected type, optimized for building HVAC and ventilation systems. A high-efficiency and energy-saving product with EC control operation.

Product Features

• Two impeller options depending on airflow and static pressure (high-volume / low static pressure & medium-volume / high static pressure)

• Aluminum impeller minimizing moment of inertia and maximizing VL effect

• Equipped with durable bearings for EC motor, IE5 efficiency class, Class F insulation, IP55 protection rating, and built-in stepless speed control

• Multi-voltage motor support — 220 / 380V, 254 / 440V, 265 / 460V, 277 / 480V

• Strong structure with anti-corrosion powder coating and operating temperature range −20~65℃

• Optional smart sensing control (temperature, humidity, speed, gas concentration, etc.) to maximize efficiency and reduce operational cost

• Customizable material per order: GI-Sheet, STS-Sheet, Mild-Steel

Main Applications

• Semiconductor equipment, local ventilation systems

• Clean room booth supply/exhaust, HVAC units such as A.H.U

• Explosion-proof structure with spark-prevention function

• Drying equipment, nuclear power plant local ventilation

• Parking lot exhaust/supply, air washer systems, special environmental control (gas concentration, temperature, etc.)

• Other industrial forced-air systems